Scania says its new V8 engines will set a new benchmark for on-road output, with an amazing output of 770 hp, while also producing improved fuel efficiency as well.

The company says total fuel savings can be as much as six per cent or more under the right conditions, when the new G33 Opticruise gearbox is included in the powertrain.

“While shifting to fossil-free transport, we must do everything to improve our current solutions,” says Alexander Vlaskamp, Scania’s Executive Vice President, Head of Sales and Marketing. “You cannot let your house burn down simply because a new one is under construction. The transition must be seamless.”

Scania claims the fuel savings are the result of extensive fine-tuning and development by Scania’s engineers, involving technologies at the forefront of internal combustion engine development.

It says that reduced internal friction, higher compression ratios, improved aftertreatment systems and a new powerful engine management system (EMS) friction and more than 70 new parts add up to a more efficient V8 diesel.

Scania acknowledges that while future, electrified transport remains at the top of the agenda, the world still depends on transport by internal combustion engine trucks – which is why its new more powerful V8s play such an important role it says.

“For a long-distance truck covering around 150,000 kilometres per year, the operator may save up to 4000-litres of fuel annually for a truck with our new V8 – a tremendous achievement in every respect,” Alexander Vlaskamp says.

The new flagship 770 hp engine produces 3700 Nm of torque between 1000-1450 rpm, an increase of 40 hp and 200 Nm on Scania’s previous King of the Road.

“We have a clear picture of where the first 770 hp trucks will start making a difference,” says Alexander Vlaskamp. “There is a strong rationale for ordering such a truck. These customers are looking for the best total operating economy, well aware of the fact that more payload means better efficiency, increased revenue and higher residual value. But I know that some of our customers also will be thrilled by the sheer joy and excitement of operating such a magnificent machine.”

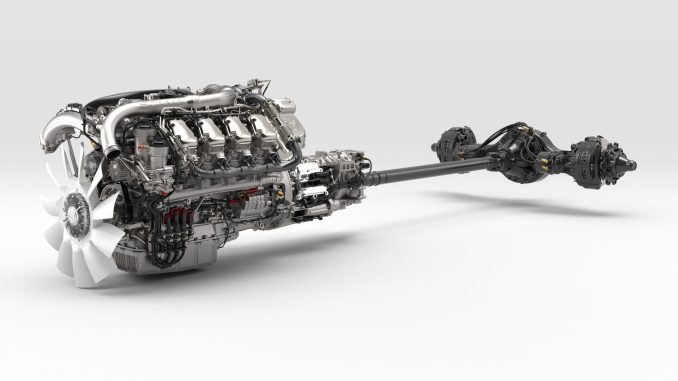

Scania’s new range of Euro 6 compliant engines comprise the 530, 590, 660 and 770 hp variants, all of which share the same 16.4-litre advanced technology compacted graphite iron block.

The 530 hp produces 2800 Nm of torque between 925 and 1325 rpm, the 590 hp produces 3050 Nm of torque between 925 and 1350 rpm, the 660 hp produces 3300 Nm of torque between 950 and 1400 rpm while the 770 hp produces 3700 Nm of torque between 1000 and 1450 rpm

For Euro 5 customers, Scania continues to offer the 620 hp V8 which will be mated to the new generation G33CM gearbox.

“We have built upon Scania’s vast V8 experience and continue to improve what generations of skilled engineers have learnt, created and achieved before us,” says Göran Lindh, Chief Engineer for Scania’s V8engines.

“There are no quantum leaps, it is all about refining things and adding the latest technology. The new EMSenables a smarter and more advanced engine control software with higher accuracy. We can calculate moreprecisely how much fuel is needed and when.”

The EMS (Engine Management System) interacts with the AMS (Aftertreatment Management System). Both are critical to meet the current and coming Euro 6 regulations regarding NOx and particles. (And not only whenthe truck is new, but also over time; the regulatory requirement is at least seven years or 700,000 km.)

Scania has added a new concept where AdBlue is injected twice: once directly after the exhaust brake and asecond dose at the “normal” position in the silencer itself. With the extra dosing, the evaporation of the AdBlueis improved during low load cycles since the temperature is higher near the outlet manifold. With the extradosing, the aftertreatment strategy is improved and also contributes to better fuel efficiency.

The updated V8 range is now equipped with a new high-pressure fuel pump where the pumping elements are individually controlled through Active Inlet Metering. The overall pressure and inlet control will be enhancedwith improved diagnostics for increased uptime and performance. The new pump is also optimised forminimising engine oil consumption. Also, the compression ratio and the maximum cylinder pressure has beenraised, to further improve combustion and fuel efficiency.

Scania says the aim when designing modern, high-performance engines is to reduce internal friction. Byreducing internal losses, substantial gains have been achieved. One alternative is, of course, to use lower viscosity, more effective modern oils with qualities that were unheard of only 10–15 years ago. But theimprovements with more advanced long-life oils in recent years are not sufficient. The engine itself must alsobe developed to make use of the new opportunities.

“Raising the pressure and the power output requires that several components inside the engine, including gears, pistons, rings, cylinder heads and valves, are refined and reinforced,” says Lindh.

“This necessitates advanced fine-tuning and improvements to reduce internal losses, especially since we alsowanted to extend maintenance intervals and strengthen durability. I am proud to say that we have managed to reconcile these somewhat conflicting objectives.”

The flagship member of Scania’s V8 family is the new DC16 123 engine.

With its output of 770 hp, it replaces the previous top-of-the-line showpiece that produced 730 hp.

“Here the biggest difference is evident,” says Lindh. “The increased power comes together with huge fuelsavings, a result we were able to reach thanks to the introduction of the latest technologies. It has an SCR-only after-treatment system, a robust, fixed geometry turbocharger and the same kind of single-bank exhaustmanifolds as the other three V8s.”

The powerful DC16 123 produces its 770 hp with the help of bigger injectors and a fixed geometry turbocharger using ball bearings. The result is faster response and improved combustion.

Shedding certain heavy components and simplifying others has lowered the weight

by up to 75 kg, compared with its predecessor.

“The new single-bank manifolds actually come with an additional advantage,” explains Lindh. “Not only arethey lighter and more efficient but they also contribute to the distinctive V8 sound, the typical ‘blatt’ that somany Scania customers and V8 fans appreciate. It does not generate more noise, but this is rather the resultof how the exhaust gases are allowed to collide, due to the firing order, inside the manifold on their way out.”

Scania has been supplying its V8 diesel engine for more than five decades with reliability, robusness andample power, with a twist of emotion included as well according to the Swedish maker .

“These are truly magnificent engines, with a short, sturdy crankshaft and smooth power delivery from themulticylinder configuration. Our famous Scania V8s are unmatched when both transport efficiency and loadcarrying capacity are in the equation,” says Lindh.

While the engine was released in Europe Scania says that at present there are no details available regarding its introduction to the Australian market